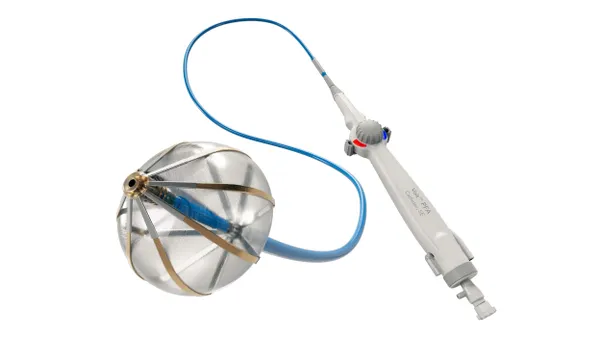

In 2020, a leading global MedTech company made a bold move. With increasing regulatory pressure on ethylene oxide (EO) sterilization and sustainability targets looming, it sought to transition one of its Class II diagnostic devices previously sterilized via EO to alternate gaseous sterilization modality. The device was low bioburden, high throughput, and seemed like an ideal candidate for a lower-emission sterilant. Packaging, the team assumed, would be a footnote.

It wasn’t.

Initial feasibility studies showed promising kill curves under the new modality, but subsequent stability testing revealed concerning material behavior. The breathable header film yellowed subtly after repeated sterilization cycles. An EVA adhesive along the blister flange began to embrittle. Most concerning, a PETG tray designed to withstand EO aeration began warping under the vacuum-pressure dynamics of the alternate sterilization cycle. One engineer described the failure succinctly: “It passed sterility, but it failed reality.”

That story is becoming more common across the industry, as sterilization shifts from a static validation hurdle to a dynamic engineering challenge.

Today’s sterilization landscape is being reshaped by three converging forces: environmental regulations (particularly EO emissions and cobalt-60 supply chain risk), rapid innovation in gaseous and low-temperature sterilants, and the increasing complexity of multi-material sterile barrier systems (SBSs). In response, medical device companies are reevaluating not just how they sterilize, but also how they design, test, and select materials from the earliest phases of development.

AAMI TIR17, updated in December 2024 and now recognized as an FDA consensus standard, reflects this paradigm shift. It introduces nuanced rating criteria based on peer-reviewed literature, known degradation pathways, and historical use, anchored across ten sterilization modalities, from radiation and moist heat to novel approaches like NO₂, ClO₂, and vaporized hydrogen peroxide.

Importantly, TIR17 doesn’t only catalog what can be sterilized. It offers a framework to anticipate how sterilization conditions interact with materials.

For example, gamma radiation remains a stalwart of terminal sterilization, but its high-energy photons can trigger cross linking in polyethylene layers, leading to embrittlement and eventual cracking. Meanwhile, e-beam sterilization offers faster throughput but shallower penetration, which may not be suitable for dense or multilayered packages. Newer modalities like nitrogen dioxide, operating at ambient temperatures, seem ideal for heat-sensitive biologics, although nylon laminates exhibit yellowing.

Packaging, in this context, becomes both the enabler and the constraint.

A single sterilization method might require breathable porosity, vacuum stability, vapor permeability, and chemical resistance, qualities that can sometimes conflict in multilayer designs. Engineers must balance the thermal softening point of polyolefins against the mechanical rigidity of PET, or the gas barrier properties of EVOH against its tendency to absorb moisture.

In the case study described above, resolution came not from a sterilization expert, but from a cross-functional team of packaging engineers, material scientists, and manufacturing specialists. They redesigned the tray in a custom PET blend with higher crystallinity, swapped the adhesive layer for a urethane-based system validated under vacuum cycling, and optimized the load configuration to reduce sterilant dwell variability. The final system passed validation with less reagent usage and a 15% shorter cycle time—while also satisfying post-market shelf life expectations.

The lesson? Material compatibility is no longer a box to check, it’s a continuous innovation conversation.

As more medical devices incorporate biologics, combination therapies, and non-traditional materials, sterilization decisions may increasingly dictate packaging design, not the other way around. Early, collaborative input across packaging, R&D, and sterilization science will be essential to ensure not just regulatory compliance, but clinical reliability, operational feasibility, and ultimately patient safety.