Introduction

Supply chain resilience is now a defining factor for success in medical device manufacturing. With regulatory requirements, patient safety and quality assurance at stake, manufacturers must navigate increasingly complex supplier networks and unpredictable disruptions. Artificial intelligence (AI) is rapidly emerging as a game-changer, enabling supply chain intelligence (SCI) that helps companies anticipate risks, streamline compliance and ensure product continuity.

Why Resilience Matters

Medical device supply chains face unique pressures. Regulatory bodies like the FDA demand rigorous traceability and documentation, while patient safety depends on the availability and reliability of every component. A single shortage or recall can delay product launches, trigger costly redesigns, or even halt production entirely.

Challenges in Medical Device Supply Chains

Globalization has expanded supplier networks, but also introduced new risks:

- Component shortages and recalls

- Geopolitical and environmental disruptions

- Regulatory compliance and traceability demand

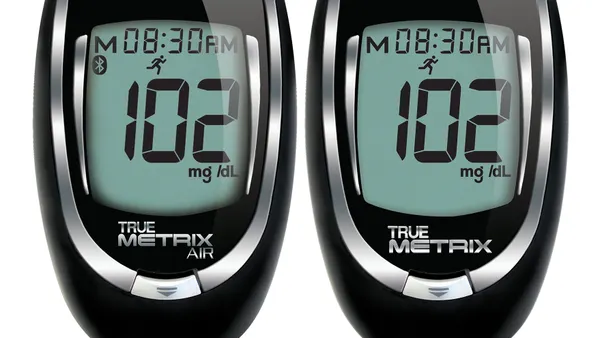

Managing these risks is especially challenging when dealing with end-of-life (EOL) components. Extended FDA approval timelines mean that electronic parts specified during new product development may reach EOL before production even begins. This can force manufacturers into expensive last time[SM1] buys (LTB) or redesigns, each with its own regulatory implications.

Why Supply Chain Intelligence Is Critical for Resilience

Supply chain intelligence (SCI) is the systematic process of collecting, analyzing and using information from all stages of the supply chain to inform key decisions and reduce risk.

In today’s global and often unpredictable business environment, SCI equips organizations with the insights needed to accurately forecast demand, monitor inventory levels, assess supplier performance, manage costs and anticipate disruptions. By transforming raw data into actionable intelligence, SCI turns the supply chain into a competitive advantage, enabling faster, more informed decision-making.

The Role of AI in Supply Chain Intelligence

AI-powered SCI platforms seamlessly aggregate data from disparate sources, suppliers, logistics and regulatory databases to provide a holistic view of supply chain health. Key capabilities include:

- Predictive analytics to anticipate disruptions and demand fluctuations

- Real-time monitoring and alerts for faster response to risks

- Automated risk identification for EOL components, regulatory changes and supplier delays

When integrated with business-critical software like product lifecycle management (PLM), SCI becomes even more powerful. PLM platforms facilitate the sharing of product information across all teams, from initial concept through design, production and disposal. Combining PLM with SCI helps medical device manufacturers take a proactive approach to supply chain risk and mitigation by gaining early visibility into bill of materials (BOM) health, so product teams gain actionable insights to design for supply chain resilience.

For example, Arena Supply Chain Intelligence (SCI) helps medical device companies proactively manage component lifecycles, identify risks early and optimize inventory strategies. Instead of relying on manual, part-by-part checks and outdated systems, teams gain instant visibility into component status and can make informed decisions about last time buys or alternative sourcing.

Case Example: Navigating EOL Components

Aubray Helm, a former supply chain manager in the medical device industry, describes how manual processes and outdated MRP systems[SM2] often left her team scrambling when parts reached EOL. With modern SCI solutions, companies can now:

- Track EOL announcements and grace periods

- Coordinate last time buys to avoid production delays

- Evaluate alternative components with real-time risk insights

Considerations for Adoption

Implementing AI-driven SCI requires:

- High-quality data and data-sharing with supply chain partners

- Change management and workforce training to leverage new tools

- Ethical and regulatory oversight to ensure AI-driven decisions meet compliance standards

Conclusion

AI is redefining supply chain management for medical device manufacturers. By enabling proactive risk management, streamlining compliance and supporting continuous improvement, integrated PLM and SCI platforms like Arena are helping companies stay ahead of disruptions and deliver safer, more reliable products. As the industry evolves, collaboration and innovation will be key to unlocking the full potential of AI in supply chain resilience.